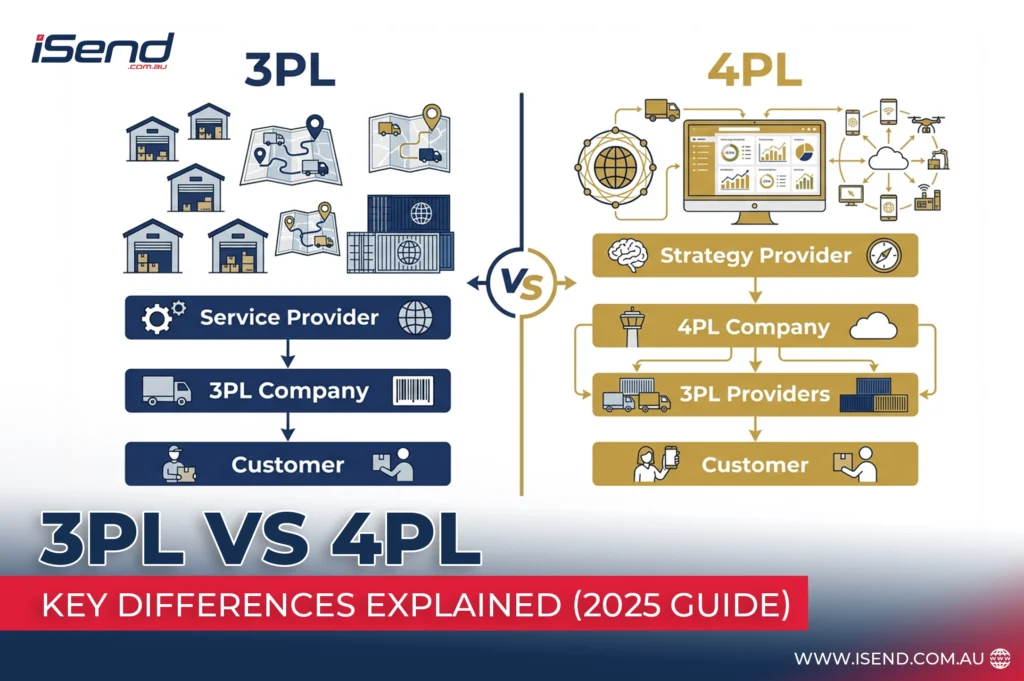

3PL vs 4PL: Key Differences Explained (2025 Guide)

As the business grows, many companies use external partners to manage their warehouses, transportation, and fulfillme...

Warehouse Logistics: Types, Benefits, Challenge...

Introduction Warehouse logistics plays a pivotal role in modern supply chain management, serving as the backbone for ...