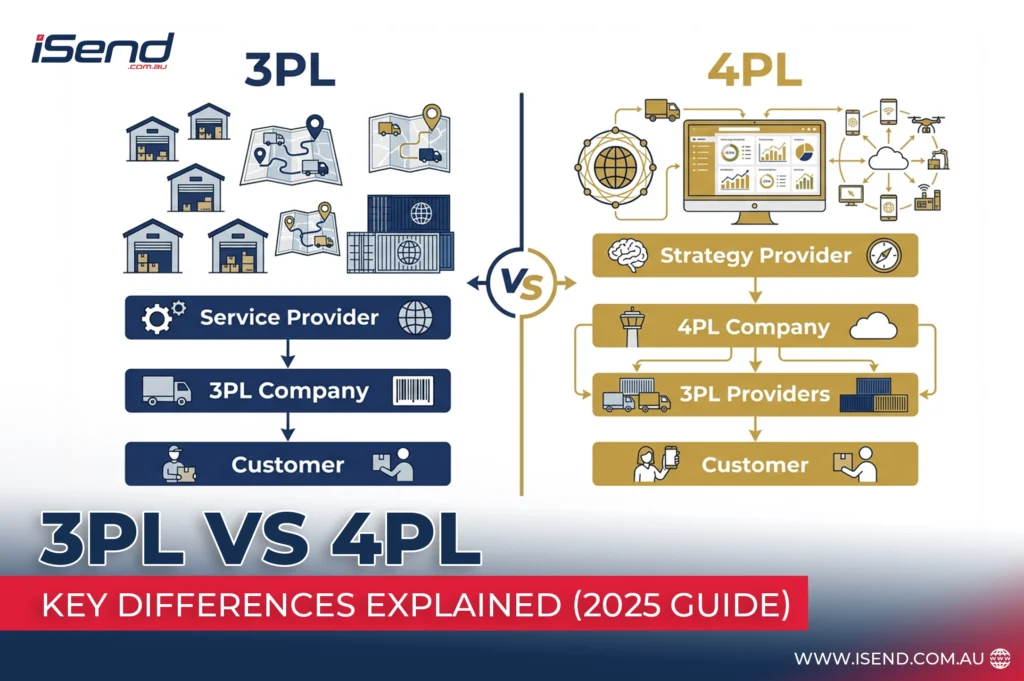

3PL vs 4PL: Key Differences Explained (2025 Guide)

As the business grows, many companies use external partners to manage their warehouses, transportation, and fulfillme...

What is 3PL Logistics? A Complete Guide for Aus...

Introduction Struggling with rising logistics expenses and ongoing supply chain headaches? In Australia, almost...