MOQ is a term you tend to hear when you buy or sell products in large volumes. It is the abbreviation for Minimum Order Quantity. Knowing the meaning of MOQ is essential for buyers and suppliers. It assists in production planning, inventory control, and ensuring business expectations.

In this guide, we shall discuss the MOQ meaning, its importance, calculation, and platforms like iSend that enable online sellers to overcome the issue of MOQ.

What Is MOQ (Minimum Order Quantity)? What Does It Mean?

MOQ refers to the minimum quantity a supplier can sell within a single order. Businesses define MOQ to ensure orders meet profitability thresholds. So, when a supplier has an MOQ of 500, you must purchase 500 or more simultaneously.

MOQ assists suppliers in determining how to accommodate their production costs. It also helps buyers determine how much investment they need to make at the start.

In simple terms, MOQ, or Minimum Order Quantity, is the minimum amount of goods required to initiate a buyer-seller transaction.

For online sellers, understanding MOQ helps with smoother fulfilment through iSend’s shipping solutions

What Does MOQ Stand For?

MOQ is an abbreviation for Minimum Order Quantity. It is the minimum possible quantity of a product that a supplier will sell.

For example, a factory manufacturing custom t-shirts can have an MOQ of 100 shirts. This guarantees they can effectively control material costs, production establishment, and shipping.

If you ever wonder, “What does MOQ mean?” or “What does MOQ stand for?”, it simply means the least quantity required per order to make the deal viable for the supplier.

Why Do Suppliers Set Minimum Order Quantities?

Companies define MOQ to balance inventory risk and cash flow. Suppliers set MOQs for several business reasons. These reasons help them stay profitable and operate efficiently.

- Production Efficiency: Producing in bulk saves time and money. It is easier to make 1,000 identical units than to create 50 separate small batches. MOQ helps suppliers maintain consistent production runs. Learn how to optimize your warehouse and fulfilment with iSend’s automated logistics system.

- Cost Recovery: Every product involves raw materials, labor, packaging, and energy costs. MOQ ensures that the supplier recovers these costs. Small orders may not cover expenses, leading to losses.

- Inventory Management: MOQ helps manage inventory. It assists suppliers in managing stock and demand. Suppliers can also sell in small batches, preventing excessive unsold inventory.

- Profitability and Cash Flow: Large orders improve cash flow and ensure suppliers profit from each transaction. Setting a Minimum Order Quantity keeps their business stable and financially secure.

For better stock control, explore Inventory Management insights

How Are MOQs Determined?

After knowing whats MOQ means, knowing how to set an MOQ is crucial. It is not a random process —it’s a careful balance between production costs and business goals. Suppliers analyze various factors before deciding. Each industry, product type, and production scale affects the final number.

Let’s look at what determines the right Minimum Order Quantity for suppliers.

Each supplier calculates MOQ differently. Several factors influence how the ideal MOQ is set.

- Profit Margins: Suppliers check their profit per unit. They set higher MOQs to earn enough total profit per batch if their margins are thin.

- Production Capacity: Factories with large machinery or high-speed equipment need to produce in bulk. Their production capacity directly affects the MOQ.

- Economies of Scale: Producing more units often reduces the cost per item. This is known as economies of scale. A higher MOQ helps suppliers reach these cost benefits.

- Packaging and Shipping Constraints: MOQ is sometimes associated with the way commodities are packed or transported. For example, when a single carton contains 100 units, the supplier may impose an MOQ of 100 to facilitate logistics.

Types of Minimum Order Quantities

Each supplier has a different MOQ system. Others are centered on the quantity of items, whereas others use order value. Knowing these types will enable you to strategize purchases wisely and match the budget to the supplier’s needs.

- Unit-Based MOQ: This refers to the minimum number of physical items that must be ordered, such as 500 pens, 100 T-shirts, or 200 bottles.

- Value-Based MOQ: Some suppliers set a minimum order value instead of quantity. For instance, they might require buyers to spend at least $500 per order.

- Supplier vs. Manufacturer MOQ: Suppliers who buy from multiple manufacturers may have smaller MOQs. However, directly manufactured goods often set higher minimum order quantities to match production costs.

MOQ Example: How MOQ Works in Practice

MOQ is simple to understand in theory, and it becomes clearer how it works in practice. This straightforward example illustrates the impact of a supplier’s MOQ on cost, profit, and order decisions. It also justifies the fact that MOQ assists in smooth business transactions.

Suppose you are ordering personalized mugs with a vendor.

MOQ: 200 mugs

Price per mug: $2

Total cost: $400

MOQ helps both sides understand limits. The supplier ensures profit, and the buyer knows the minimum investment required.

This simple MOQ example shows how Minimum Order Quantity works in real business situations.

Advantages & Disadvantages of MOQ

Depending on the scale of the business, MOQ will either make or break a deal. While it can bring advantages such as cost-cutting and efficiency in production, it can also restrict small buyers. To understand this better, let us evaluate MOQ meaning with its pros and cons.

Advantages:

- Cost Effectiveness: With bulk production, the cost per unit is lower

- Consistency: Huge orders imply consistency

- Improved Cash Flow to Suppliers: Suppliers get regular money

- Less complex Inventory Control: Foreseeable production and inventory

Disadvantages:

- Expensive Startup: Purchasers have to pay higher amounts at the beginning.

- Storage Problems: Small enterprises may find it challenging to operate a large inventory.

- Reduced Flexibility: Purchasers are not able to test small quantities of products.

Concisely, MOQ possesses advantages and disadvantages. This is aimed at harmonizing the two ends to ensure smooth business operations. Learn more about how small businesses manage inventory in iSend’s stocktake guide

How to Calculate the Ideal MOQ for Your Business

Finding your ideal MOQ is no guesswork. It is the combination of data, demand, and cost. A correct MOQ can be implemented to avoid overstocking or underordering. It helps you match your cash flows and running inventory.

To calculate the right MOQ, consider:

- Demand Forecast: Find out how many of your customers will buy.

- Unit Cost: Labor, packaging, materials, and delivery.

- Storage Capacity: See the amount of space available to store inventory.

- Cash Flow: You need to be able to pay the initial cost.

Simple Formula:

MOQ = (Total Fixed Costs + Target Profit) ÷ (Selling Price – Variable Cost per Unit)

This will explain the number of items you need to sell to be profitable and break even.

For better planning, check out demand planning strategies to align production with demand.

MOQ vs EOQ (Economic Order Quantity): What’s the Difference?

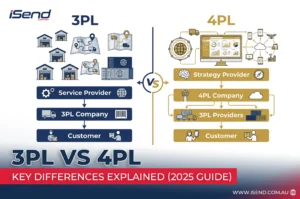

Most people confuse MOQ and EOQ. Although the two are associated with ordering quantities, their uses are different. MOQ is supplier-based, and EOQ is buyer-based. It is only possible to deconstruct their differences.

Both play a key role in Inventory Management

MOQ and EOQ are dissimilar.

MOQ (Minimum Order Quantity): This is the lowest number of units a buyer must purchase, set by suppliers.

EOQ (Economic Order Quantity): Set by buyers. It’s the ideal quantity a business should order to reduce total costs, like storage and ordering.

In short, MOQ benefits suppliers, while EOQ benefits buyers. Both play a key role in Inventory Management and business planning.

How iSend Simplifies MOQ Challenges for Online Sellers

Online sellers often face MOQ problems. Small businesses may not have enough funds or space to buy large quantities.

iSend helps solve this issue. It connects sellers with trusted suppliers offering flexible MOQs. Sellers can buy smaller quantities, manage cash flow better, and reduce storage risks.

With iSend, you can:

- Find suppliers with low Minimum Order Quantity options.

- Split orders across multiple buyers.

- Ship and manage logistics on a single dashboard.

- This simplifies Inventory Management and assists online sellers in expanding without enormous investments.

See how iSend helps eCommerce businesses handle shipping

Final Thoughts: Why Understanding MOQ Matters

Knowledge of the meaning of MOQ is crucial in any business. It influences the price, production, and profits. Understanding the MOQ will allow you to negotiate with suppliers more effectively.

Knowing how Minimum Order Quantity works will save you money and help you establish good relations with suppliers, whether you’re an online seller or a new entrepreneur.

Software such as iSend simplifies it even more with flexible MOQ solutions. A successful business balances its order quantity with its demand and cash flow.

Want to see how others are succeeding? Watch Sarah’s iSend success story.

FAQs

- Why do suppliers have an MOQ?

Suppliers will impose an MOQ that will cover the cost of production and profitability. It maintains their efficiency and does not deal with small, unprofitable orders.

- How is MOQ calculated?

MOQ is calculated by examining the cost of production, material cost, profit margin, and demand projections. Suppliers modify it depending on these factors.

- What are the disadvantages of MOQ?

Its primary drawbacks are its expensive initial cost and excessive storage requirements. Small businesses might be unable to purchase in bulk.

- What is the purpose of MOQ?

MOQ is designed to ensure that suppliers receive their costs and can maintain an efficient production level.

- What is MOQ?

MOQ means Minimum Order Quantity, or the minimum quantity that a supplier will sell in an order.

- What does MOQ mean?

MOQ is the lowest order quantity required to deal with the supplier.

- What does MOQ stand for?

The short term for Minimum Order Quantity is MOQ. It is a generic word used in all manufacturing, retail, and wholesale sectors.